What if the silent power source in your garage has a story of precision and craftsmanship behind it? The journey of a generator, from raw materials to a finished product, is a testament to modern engineering. A generator is a device that people can take recourse to when important times occur, such as a job site up in the woods. It is something we always take into thought when we require it, but it is a very deliberate process to create. A factory pure generator is an engineering and labour-intensive manufacturing process that results in high-quality and reliable products. Learning more about the construction of these mighty machines helps us to understand technology and better appreciate the technology that keeps our homes and businesses running smoothly.

The Core Components of a Generator

The creation of a generator begins with important parts. Each component is carefully selected and assembled.

The Engine and Alternator

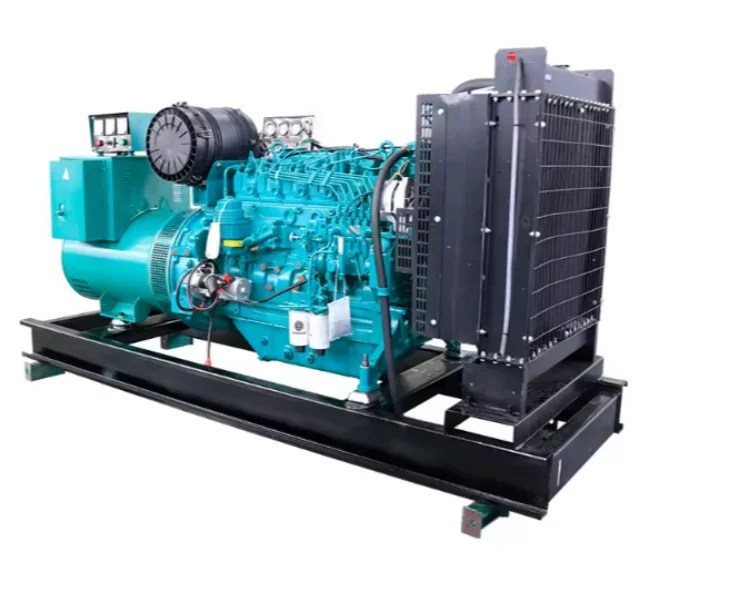

The generator can be described as the heart of its engine. It is presented as the mechanical energy utilised by the alternator that later converts it to electricity. These engines are strictly constructed in a factory to make sure that they are tough and powerful. It is also the alternator, which is the component that generates the electric current that has been designed to offer a smooth and steady amount of power output. This constitutes an important step by which a pure generator is fabricated.

The Control Panel and Fuel System

The generator has a brain named its control panel. It enables one to observe and regulate the device, the machine, and it also safeguards the generator against destruction. A complicated control panel assists in sustaining the clean power production, which is a characteristic of a pure generator. The fuel system is efficient in the sense that it allows long-term generation without facing any interruption.

The Importance of Quality Control

The manufacturing process is incomplete without a quality check. This is what makes a generator a reliable and safe product.

Testing and Certification

A pure generator in a factory is the outcome of stringent testing. All of the units undergo testing to guarantee the full extent of safety and performance specification standards. These are the inspection of the power output, stability of the waveform and the general functioning of the machine. This action is what will make a user have utmost confidence in his/her generator that it will perform optimally needed most.

It is not only the story of utilising a generator, but it is the story of creating a generator. A factory pure generator is a product of modern engineering and quality production, quite literally built with care in the precision-designed assembly of its core components, to a rigorous testing process. By having the knowledge of this process, we can begin to understand that the rough power that it delivers to us is not a fluke but rather a well-calculated and calibrated move throughout the factory to your home or organisation.